March 29, 2023

March 29, 2023

Oftentimes floor flatness/levelness testing is one of the more misunderstood testing requirements involved in concrete inspections. Disregarding this type of test could result in uneven flooring, compromising the safety of people and equipment, especially in areas with high foot and equipment traffic. If uneven flooring is discovered toward the end of the project, the cost to repair the issue would require unanticipated additional funding. This is why it is so important to hire a highly experienced company, such as NOVA, to perform this timely test.

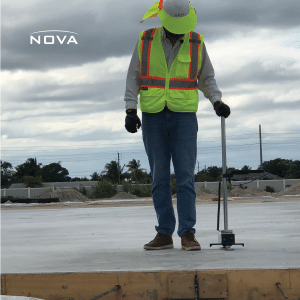

What is floor flatness/levelness testing? Featured in this photo, our NOVA Fort Lauderdale Project Engineer is caught in action performing this exact test. The project site consists of the construction of a warehouse with an approximate area of 190,495 square feet. Among the various testing services NOVA has been selected to provide for this project, we are providing floor flatness/levelness testing and reports after each concrete pour. Floor flatness is a measurement of whether the concrete slab has bumps or waves as you move across the slab. Levelness means how closely the floor conforms to the specified slope. These two factors seem so simple, but when it comes to proper and safe construction, they mean so much.

How is floor flatness/levelness testing measured? The testing of a concrete slabs flatness and levelness is governed by ASTM E1155 and gives (2) two numerical values, FF for Flatness and FL for Levelness. According to the American Concrete Institute (ACI), floor flatness is measured by tracking the difference in elevation between two points 1 foot apart and comparing them with every other 1-foot elevation change across a measured distance or “run.” Floor levelness on the other hand compares the change in elevation over a distance of 10 feet, by determining the net change. A profiler takes measurements of elevation using an inclinometer, a device that measures angle relative to level. The profiler is a box with two feet on the bottom, exactly 12 inches apart, and a long handle so the operator can hold it while standing. The operator walks in a straight line down the slab, moving the device 12 in. at a time, often covering a distance about equal to the width of the room on each run. Multiple runs in two directions are needed to accumulate the statistically significant sampling that meets the ASTM standard’s minimum data requirements. The device takes a vertical angle measurement at each step and converts those angles into changes in elevation.

To learn more about the many services NOVA can offer, be sure to visit usanova.com or reach out to us via the contact us link.

Photo credit: Sandro Maldonado, Fort Lauderdale, FL Project Engineer